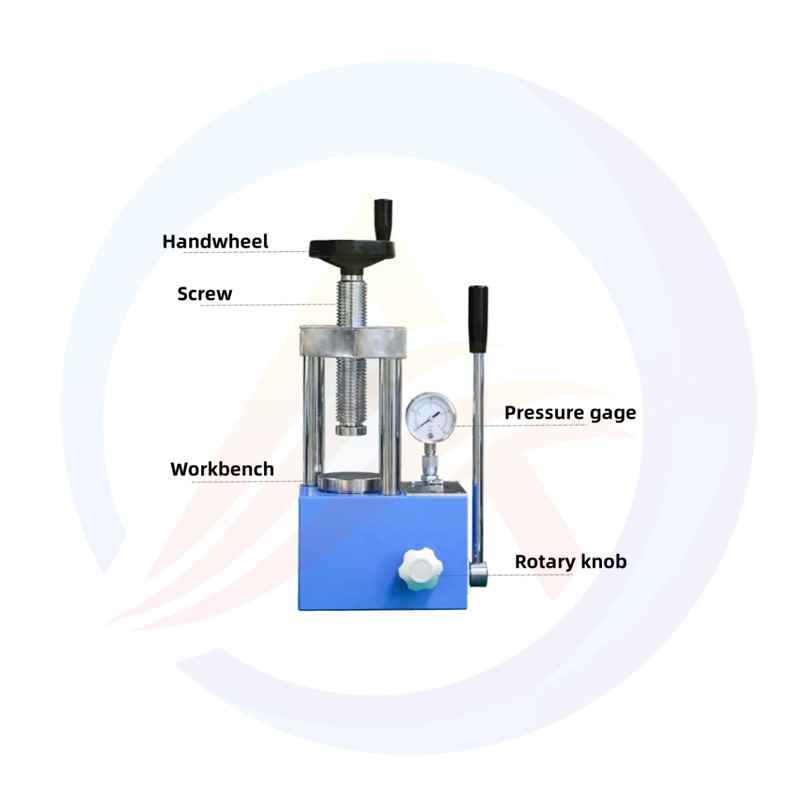

Q1:What is powder press mahicne?

Powder press machine is an industrial equipment, mainly used to press various powdered materials into products with a certain shape, size and density. By applying mechanical pressure, the powder particles are extruded and combined to achieve molding. Common in battery, ceramics, powder metallurgy and other industries, can improve production efficiency, to ensure the stability and consistency of product quality.

Q2:The role of the powder press?

A: The role of the powder press machine is mainly to compactthe powder material, which can manufacture electrode sheets in the battery production to improve the battery performance; In the ceramic industry can make ceramic body, to ensure product accuracy; In the field of powder metallurgy, it is used to produce metal parts, improve material density, enhance mechanical properties, but also improve production efficiency, reduce costs, and ensure the stability of product quality.

Q3:Operation mode of powder press machine

A: Powder press machine operation mode is divided into three kinds. Manual operation is manual feeding, by the handle, button control pressure head, set parameters by experience, low efficiency; In semi-automatic operation, material conveying depends on machinery, manual discharge, and parameters are set by electronic controller; Automatic operation is the whole process automation, set parameters in the operation interface, automatic operation of the equipment, high efficiency and stable quality.

Q4:How to get technical support after purchasing?

A: Our factory provide online technical support in English , you can easy catch us online by Skype, Wechat, and Email, if you need any remote assistant support, then we will support you though Team Viewer.

Q5:What's the warranty for the items?

A: We are very confident in our products, and we pack them very well, so usually you will receive your order in good condition. Any quality issue, we will deal with it immediately. Warranty for equipment is 1 or 2 year (12 or 24 months depends on the type of products), If the equipment parts are damaged due to non-human factors within one year, we will provide replacement parts free of charge.